Services

It's Time to Start Your JOURNEY WITH US

We are at the forefront of waste management service delivery to the oil and gas sector in East Africa and currently own the largest privately owned local environmental and waste treatment facility in Uganda, with a built up capacity of 1000 tons/day of cuttings and 400m3/day of drilling fluids.

We aim to provide services to the oil and gas companies regarding treatment, recovery, and disposal of drilling fluids, drilling cuttings and other related oilfield drilling wastes.

We adopt different technologies and equipment to handle different quantities and types of drilling waste: both hazardous and non-hazardous. We therefore ensure resource recovery and reuse/recycle to the maximum possible extent and considering disposal as only a last resort.

We are now revolutionalising the treatment processes in Uganda by investing in the state of the art equipment, systems and processes including the installation of two (02) thermal desorption units and use of mud skips to transport our waste.

We also offer solids control technologies, oilfield water services, all engineering services including but not limited to electrical engineering and White Nile.

Why choose WhiteNile Consults

WhiteNile Consults is the top choice for oil waste management services due to our extensive experience, stellar reputation, and unwavering commitment to providing expert guidance and support to our clients.

- Experience: Benefit from our extensive industry knowledge and expertise.

- Reputation: Trust in our track record of excellence and reliability.

- Guidance: Receive expert support every step of the way to ensure success.

What You Get

When you choose to work with WhiteNile Consults, you gain:

- Efficiency: Streamlined processes and effective solutions tailored to your needs.

- Reliability: Dependable services and consistent results you can count on.

- Expertise: Access to a team of experienced professionals dedicated to your success.

Services

BIOREMEDIATION

White Nile presently employs bioremediation processes to stabilize and reduce the volume of water based mud as much as possible.

Bio-stabilisation of cuttings is brought about by micro-organisms available in manure and peat soil ; requiring the organic component of waste for their cell metabolism while extracting inorganic contaminants for their cell genesis.

A stable solid waste material (compost) is obtained after a specified period of controlled composting on bio- platforms. Stabilisation rates achieved are up to 99% below disposal standards and volume reduction is up to 40% of the total composting material after the composting period.

White Nile bioremediation plant has a built up capacity of 450 tons/day of cuttings.

The stabilized material after composting is recycled in making construction blocks, landscaping, paving pathways, and reconditioning of afforestation area.

solidification & stabilisation

White Nile employs solidification and stabilisation processes to treat both water based mud and cuttings with unrecoverable oil contents. Portland cement is used to macro-encapsulate the cuttings thereby immobilizing the organic and inorganic contaminants in solidifying hydration product

of cement.

Stabilisation rates are up to 99% below disposal standards and volume reduction is about 45% of the original material. However, volume reduction increases with time as material continues to solidify after disposal.

Solidification and stabilisation plant has a built up capacity of 1000 tons/day of cuttings. The solidifying material is disposed in a sealing

type engineering hazardous waste landfill. Our landfill site locations are selected putting into accounts proximity to receptors, geological sensitivities, management of water resources and lining systems.

Our landfill engineering, construction, operation and closure activities are subject to a comprehensive construction quality control and assurance process.

White Nile landfills are monitored for a period of 25years to ensure mitigation of any post closure environmental, Health, and Safety concerns.

Our landfill operations are designed to meet both local and international standards and are intended for hard end use as parking yards, golf courses.

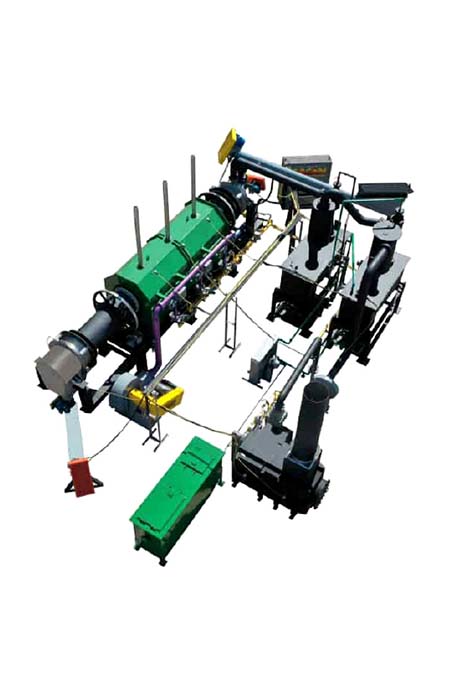

thermal desorption technology

White Nile presently employs bioremediation processes to stabilize and reduce the volume of water baseWhite Nile is in process of installing two (02) Thermal Desorption units (TDU) with acombined capacity of 24000 tons per annum to treat oil based cuttings.

The treatment process for Oil-Contaminated Drill Cuttings involves an Indirect thermal stripping process where the oily cuttings are heated in a controlled chamber to temperatures between 3250c and 5000c for heavier oils, to enable the extraction of liquids.

Furthermore, the process is fully computerized and controlled and able to recover oils without altering the integral molecular structure. Oil residue on treated cuttings (Cleaned Cuttings) will be less than 0.5% (NEMA requires <1% oil on cuttings).

The recovered oils are intended for reuse in formulation of new drilling fluids while the cleaned cuttings shall be recycled in construction blocks making. mud as much as possible.

Bio-stabilisation of cuttings is brought about by micro-organisms available in manure and peat soil ; requiring the organic component of waste for their cell metabolism while extracting inorganic contaminants for their cell genesis.

A stable solid waste material (compost) is obtained after a specified period of controlled composting on bio- platforms. Stabilisation rates achieved are up to 99% below disposal standards and volume reduction is up to 40% of the total composting material after the composting period.

White Nile bioremediation plant has a built up capacity of 450 tons/day of cuttings.

The stabilized material after composting is recycled in making construction blocks, landscaping, paving pathways, and reconditioning of afforestation area.

WASTE-WATER TREATMENT

White Nile waste-water treatment plant has a built up capacity of 400m3/day. It consists of a shale shaker unit, chemical enhanced de-watering units, chemical enhanced de-oiling units, and activated carbon and sand filtration units.

Waste water treatment process involves coagulation and flocculation with organic and inorganic flocculants and solid-liquid

phase separations in a dewatering unit; reducing the levels of particulate matter, inorganic, and organic contaminants up to 99% below discharge standards.

The oily content(>1% v/v oils) of the resulting filtrate is disintegrated in a chemical enhanced de-oiling unit; and a clear liquid product is obtained in subsequent filtration in activated carbon and sand filter units.

The recovered treated water(65% v/v) is recycled as process water in solid waste treatment while the generated sludge is mixed and treated with the cuttings.

COMMITMENT TO EXCELLENCE

At WhiteNile Consults, we’re dedicated to excellence in every aspect of our oil waste management solutions. With a steadfast commitment to environmental stewardship and sustainable practices, we strive to deliver innovative and tailored solutions that meet the unique needs of our clients in the oil sector. From waste characterization and assessment to collection, treatment, and disposal, our team of experts ensures the safe and efficient management of waste materials, helping our clients minimize environmental impact and achieve regulatory compliance. Partner with WhiteNile Consults for comprehensive waste management services that prioritize sustainability and drive positive change in the oil industry.

Address

Plot1 Water Lane, Naguru.

P.O. Box 9421, Kampala.

Phone: +256 393 246 524

Email: info@whitenileconsult.com

Hours

Mon - Fri : 8.30AM to 5.30PM